Made with a conventional PCB process, they are durable, compact and tolerant of misalignment between target and sensor, as well as large gaps. The large gaps allow sensor and target to be encapsulated in separate housings.

Axial Sensors are Type 3 (find out more about how sensors are classified and what this means for CTU selection in our FAQ) which use four coils - two of these excite the resonator in the target and all four detect signals coming back from the resonator, to be processed by a CAM312 IC.

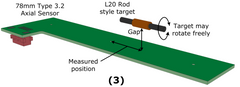

The images here show (1) a 78mm Type 3.2 Axial Sensor Assembly, (2) an illustration of a float level sensing application using an air core target design and (3) an Axial Sensor working with a wound ferrite rod style target. Other target designs are possible - see datasheet for options.

Features

- Full absolute linear sensing

- 8-layer PCB process

- Works with a wide range of target designs

- 5 wire connection designs

Applications

- Valve position sensing

- Actuator position feedback

- Liquid level sensing by detecting float height

- Electronic reading of variable area flow meters

- Syringe plunger position measurement

Performance

- Linearity error < ±0.2%

- Noise free resolution >10 bits

- Gap up to 10 mm

Testing and development

The Axial Sensor Development Kit is recommended for getting started and it includes a 78mm Type 3.2 Axial Sensor Assembly (Part No 013-0057).

| Part No | Description |

|---|---|

| 013-7005 | Axial Sensor Development Kit |

| 013-0057 | 78mm Type 3.2 Axial Sensor Assembly |